Anubhav SahuMoneycontrol Research

With just a few days to go for GST implementation, the chemical sector in general and the dyes and pigments sub-sector in particular are witnessing a pause in supply chain movement after a drastic destocking. So, while we look at the short-term supply disruption, we are also cognisant of the fact that organized players in the industry should benefit from the transition as around half the sector’s turnover comes from unorganised players. Additionally, the environmental crackdown in China continues to aid market share growth for the Indian domestic firms.

We took stock of the situation through our channel checks with the dyes, pigments, coatings manufacturers, dealers, retailers in the key hub of Kanpur and the industrial belt of Gujarat. Most of the mid-size manufacturers have curtailed their overall production and in some cases stopped the process, and are unlikely to revive it before second week of July. In the B2B segment, some of the manufacturers have given directives to industrial clients to place orders after July 10, when their systems are expected to be in place for GST.

Our survey with the supply chain participants indicated that small dealers and stockists have virtually cleared their stocks. Large dealers and traders in Delhi and Kanpur have destocked their inventory by as much as 80 percent. Some suppliers from Mumbai and Gujarat have also virtually stopped the transit flow with a view to resuming post GST implementation.

Value chain: Dyes and pigments industry

Source: Moneycontrol research

So why such a massive destocking?

GST rates, by and large, are at 18 percent for most of the products in this segment (dyes, surface coatings, varnishes, pigments). This is not much different from the existing applicable rates. In UP, the pre-GST rate is about 17.5 percent (12.5 percent excise and 5 percent VAT) and in Gujarat it is 18.125 percent.

However, there’s a fear of margin erosion that’s partly fueling inventory destocking.

1) Where proper excise documentation not available (70 percent of the cases), implied input cost credit is 40-60 percent only. So, the inability to claim full input tax credit on the goods purchased before GST might weigh on margins.

2) Inventory of goods purchased and available six months prior may not be eligible for the input tax claim.

3) Cost of initial tax compliance and training employees is a factor.

4) Lastly and probably quite importantly, the prevalence of the huge unorganised sector in the dyes, pigments and coatings businesses will impact de-stocking. This segment will try to get rid of older stock as they now will have to register under GST. Pre-GST this segment benefited from certain tax evasion measures to remain competitive versus the organised sector.

With GST in place, supply chain participants have understood well enough that billing to unregistered firms, a popular way of tax evasion, will not be possible now. As the possibility of higher margins due to lower tax compliance vanishes, organized players have a chance of picking up market share.

Must Watch: Another Tryst With Destiny! How GST Will Change Your Life after July 1

China Opportunity

The dyes and pigments industry has in the last few years largely benefited from the China opportunity. Increased compliance for environmental norms had led to closure of various chemical manufacturing facilities in China, leading to reduced supply and resultant opportunities for the Indian manufacturers.

Of late, some of those facilities in China have come back to life like Hubei Chuyuan – one of the biggest integrated dyestuff manufacturers, but operating with a low capacity utilization. In our conversation with Mayur Padhya, CFO Bodal Chemicals we learnt that environmental compliance cost in terms of setting up effluent treatment plant (CETP) constitute a huge cost (about 20 percent). This means that the cost arbitrage Chinese manufacturers were enjoying due to non-compliance would be lost. Additionally, China manufacturers no longer enjoy a huge export incentive like they did in the early 2000s. Similarly, labour cost arbitrage is also lost. In fact for the dyes and pigments industry, some of the Indian manufacturers highlighted that wage cost in some cases for Chinese manufacturers is now 2.5x that of India.

So this means that the opportunity coming in due to China’s transformation is more structural in nature and organized players in India having an established capacity and environmental compliance can meet the demand requirement.

Spurt in Sector’s Earnings Growth

Due to a huge capacity expansion within the sector, export opportunity and lower growth in raw material prices, the sector witnessed a significant jump in earnings - 11 percent CAGR in topline for last five years. Earnings received a boost on account of lower raw material cost and reduced interest cost.

Table: Sector aggregate financial trend

Source: Moneycontrol research

Among the integrated players, Bodal Chemicals stand out with its 17,000 MT capacity for dyes, 30,000 MT for dye intermediates with 10 percent and 20 percent market share respectively. The company has huge capacity expansion plans whereby in next 4.5 years, dyes manufacturing is expected to increase to 41,000 MT. Though at 14x trailing PE, the company appears reasonably valued, huge volume increase in medium term is comforting. Along with that company plans to use 90 percent (currently 40 percent) of the dyes intermediates for captive consumption in next 2-3 years and thus benefiting from margin expansion due to this vertical integration. Another promising company to look at it is Meghmani Organics with a 31,000 MT capacity for pigments and 68 percent sales coming for exports. Recently, both the companies reported improved traction in the domestic businesses.

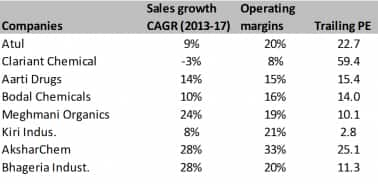

Table: Key manufacturers financial metrics

Source: Moneycontrol research

So, while the sector continues to grapple with supply chain slowdown in the near term, there is enough scope for the organised players to increase the market share. Investors can take advantage of this transition by positioning accordingly.

Discover the latest Business News, Sensex, and Nifty updates. Obtain Personal Finance insights, tax queries, and expert opinions on Moneycontrol or download the Moneycontrol App to stay updated!

Find the best of Al News in one place, specially curated for you every weekend.

Stay on top of the latest tech trends and biggest startup news.